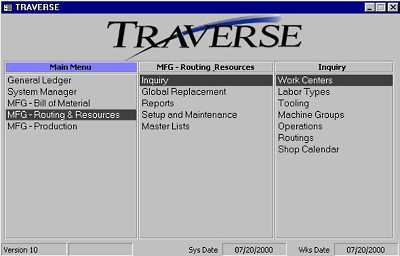

Manufacturing - Routing and Resources

A complete set of tools to

define how and what you do

The labour, machinery, and

tooling elements of manufacturing can be as

crucial as the component materials you use.

These are the elements that can cause production

to come to a crawl and cause costs to far exceed

projections. The Traverse Routing and Resources

application provides the functionality to define

these important pieces of your manufacturing

software solution.

Working with the Bill of

Materials module, the Routing and Resources

application defines the elements such as work

centers, labour, machinery, and tooling. In terms

of costs and times, these elements make up the

process side of the manufacturing bill of

materials.

By breaking down the process

in the labour types, machine groups, and tooling,

Routing and Resources enables you to define

operations as a combination of these elements.

Routings are then created as a set of

step-by-step operations and can be used in the

Bill of Materials application without needing to

be recreated every time.

The system allows for the

definition of queue time, setup time, run time,

wait time and move times. All times are defined

in terms of seconds, minutes, or hours. Overlap

logic is used to determine the rate of

pass-through. Flexible costing algorithms can be

set up for labour and machinery. Overhead methods

can be unique for each work center.

Routing and Resources also

provides a sophisticated base for future

customization with a comprehensive tooling

database, labour and machinery pricing

algorithms, and a complete shop calendar

feature.

From Tooling to Labour, the

Routing and Resources module is flexible enough

to grow with your company. |