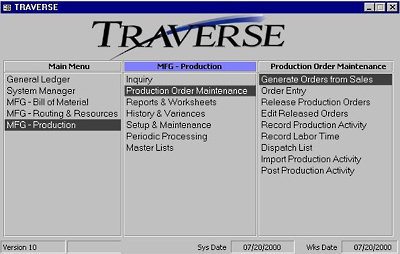

Manufacturing - Production

Keep your finger on the

pulse of production

Production is where it all

comes together. Your software must be able to

tell you today's production status, what is

going to happen next, and what happened

yesterday. The Traverse Manufacturing Production

application is up to the test. Online inquiry

into existing production orders shows percentage

complete based on time and materials and gives

you detailed information of the status of each

production process.

Once created, production

orders can be completely edited via the visual

editor in a drilldown manner for the flexibility

many manufacturing environments require.

Activity recording can be imported from an

external source such as an automated time card

or bar code data collection system, or it can be

entered manually.

A variety of worksheets can

assist you in this process. Each one has a

specific focus in terms of what to pull, which

operation to run, and where to go next. Special

worksheets help expedite subcontracted

processes.

Visual tools such as videos

and pictures are readily available to assist in

the process. A sophisticated dispatch process

allows you to set the sequence of for each

process and keep things moving smoothly.

Extensive variance reporting

enables you to see when, where—and, most

importantly—why variances took place in terms of

time, usage quantities, and final production.

The Production module provides

you with several approaches to recoding

production activity to make data entry as

efficient as possible. |