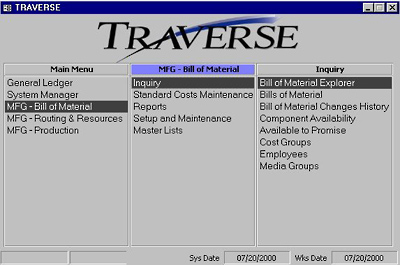

Manufacturing - Bill of Materials

A comprehensive base for a

complete, easy-to-use manufacturing solution

The key to a successful

manufacturing software implementation begins

with the Bill of Materials. A bill of materials

(BOM) defines the products structure in terms of

materials and provides an optional connection to

plant resources such as machinery, tooling, and

labour defined by a bill of routing. The Bill of

Materials application provides a solid base for

production activity to be defined, tracked and

reviewed. It also enables more advanced software

such as MRP and CRP to be properly utilized.

Traverse Manufacturing Bill of Materials is the

place to start.

The software functionality

provided gives you the tools you’ll need to

define both the simplest and most complex bills

of material. Designed to allow you to start

simple and build from there, the maintenance of

the bills of material provides advanced features

such as detailed routing, multiple routing

definition, mixed unit of measure, cross group

costing, scrap tracking, and total visual

documentation.

Revision numbers, effective

dates, and drawing numbers help to further

define the BOM. You’ll find that the

sophisticated feature set built into this

product is comparable to software that is priced

substantially higher. Yet, you can set up

simple, material-only bills quickly and with

minimal work.

Features like a text file

import enable you to bring engineering bills

directly into your current BOM database.

Standard cost maintenance, global component

replacement, BOM change history, and a variety

of inquiry functions give you automated update

abilities and quick access to vital information.

The Available to Promise and

Component Availability functions take you beyond

typical BOM functionality, giving you valuable

insight into current and future availability.

The Bill of Materials module

offers a robust set of built-in features. |